Injection moulding is usually a preferred and very productive production course of action utilized to produce plastic parts in huge volumes. From everyday such things as bottle caps and containers to complicated automotive and clinical parts, injection moulding plays a important job in modern day production throughout an variety of industries.

How Injection Moulding Functions

The injection moulding course of action starts with Uncooked plastic resources—typically in the form of pellets—currently being fed right into a heated barrel. The fabric is melted after which injected in the steel mould cavity underneath underhand. The mould, commonly produced from steel or aluminium, is precision-engineered to create the desired shape of the products or services.

As soon as the molten plastic fills the mould and cools, it solidifies from the remaining shape. The mould then opens, in addition to the part is ejected. The cycle then repeats, permitting higher-speed, repeatable producing.

Vital Elements of your Approach

The mould: The heart during the system, this Software establishes the shape and composition of your remaining part.

The device: Injection moulding equipment are detailed in more info their clamping force, which could range between two or three tonnes to a number of hundred tonnes.

The fabric: Lots of plastics works incredibly effectively, including ABS, Polypropylene, Nylon, and Polycarbonate, Each and every with specific Attributes suitable for various purposes.

Advantages of Injection Moulding

Injection moulding is broadly employed because of its quite a few positive aspects:

Higher efficiency: As soon as the Preliminary set up is total, manufacturing is amazingly rapidly, typically with cycle situations calculated in seconds.

Regularity and precision: The procedure makes certain just about every component is similar, well matched for higher-quantity production.

Negligible squander: Surplus plastic is usually reground and reused, generating the technique a lot more sustainable.

Style and design overall flexibility: Intricate shapes, good details, and completes can all be attained With all the proper mould design.

Popular Programs

Injection moulding can be employed in pretty much any market. In automotive, it generates interior elements and housings. In healthcare, it creates sterile syringes and containers. In gadgets, it’s utilized by casings and connectors. The flexibility of your process leads to it to get an important part of present day production.

Summary

Injection moulding is usually a potent, Price-effective system for manufacturing large-high quality plastic parts. Its pace, scalability, and precision allow it being quite possibly the most effectively-preferred option for brands throughout the world. Regardless of whether you’re organising a compact gadget or maybe a complicated industrial component, injection moulding provides reliability and efficiency at scale.

Edward Furlong Then & Now!

Edward Furlong Then & Now! Rick Moranis Then & Now!

Rick Moranis Then & Now! Andrea Barber Then & Now!

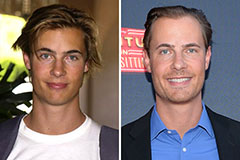

Andrea Barber Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now!